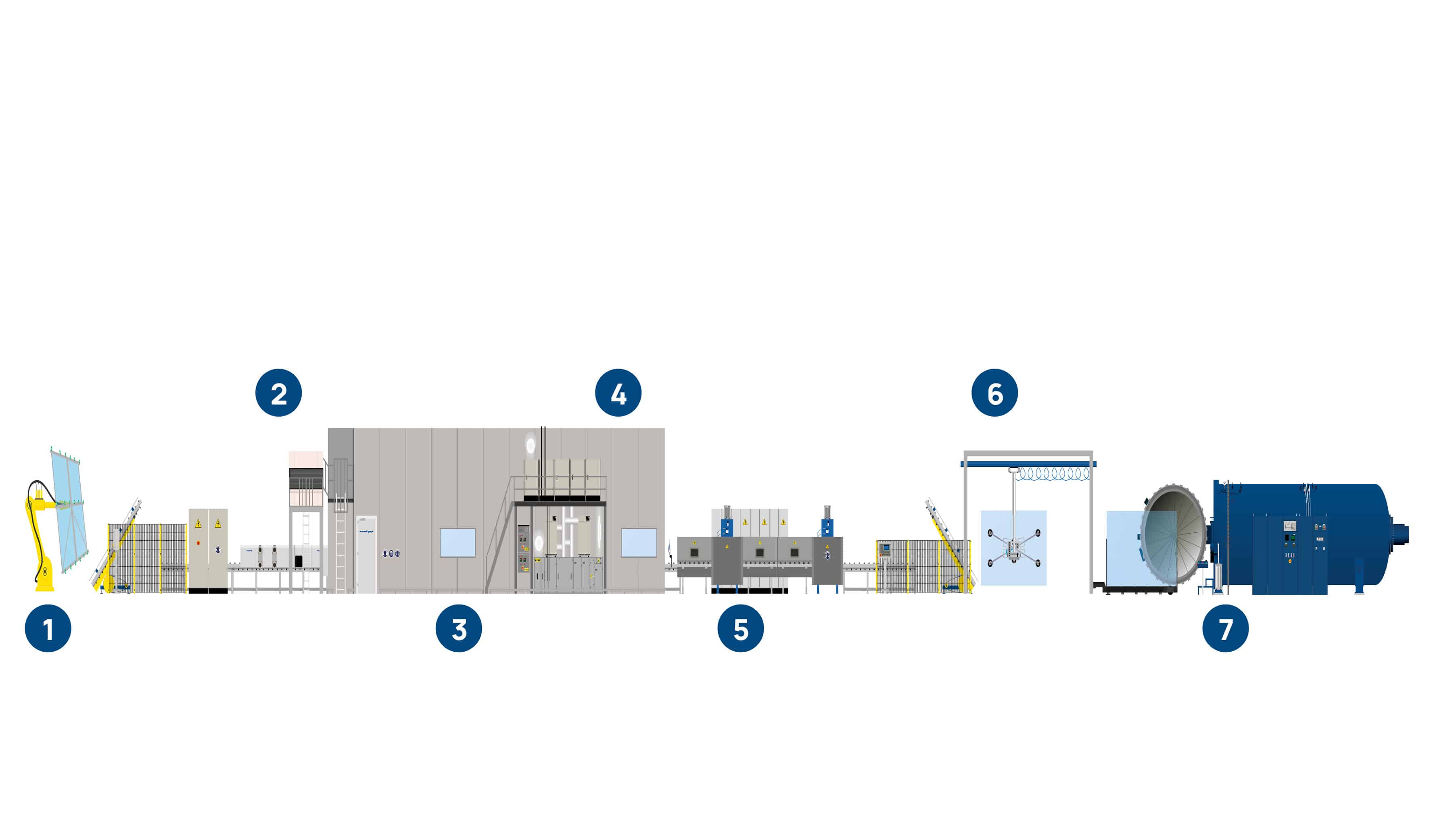

Laminating process

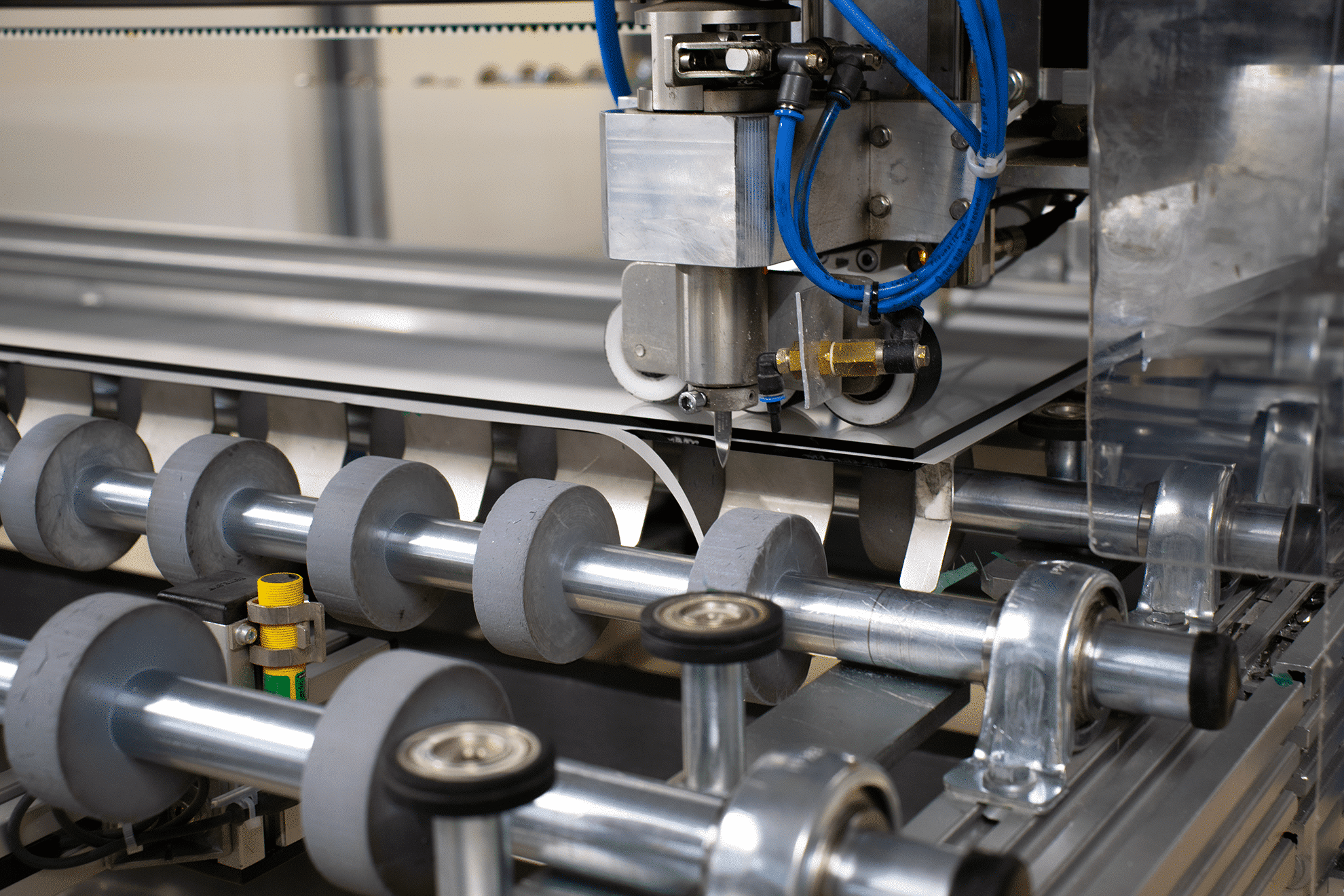

Step 1: Lay down

The first step in the laminating process is placing the separate glass sheets onto the laminating line. Our robot places the glass sheets one-by-one on the tilting table. As the tilting table sends the glass towards the second step, the robot picks up the second glass sheet.

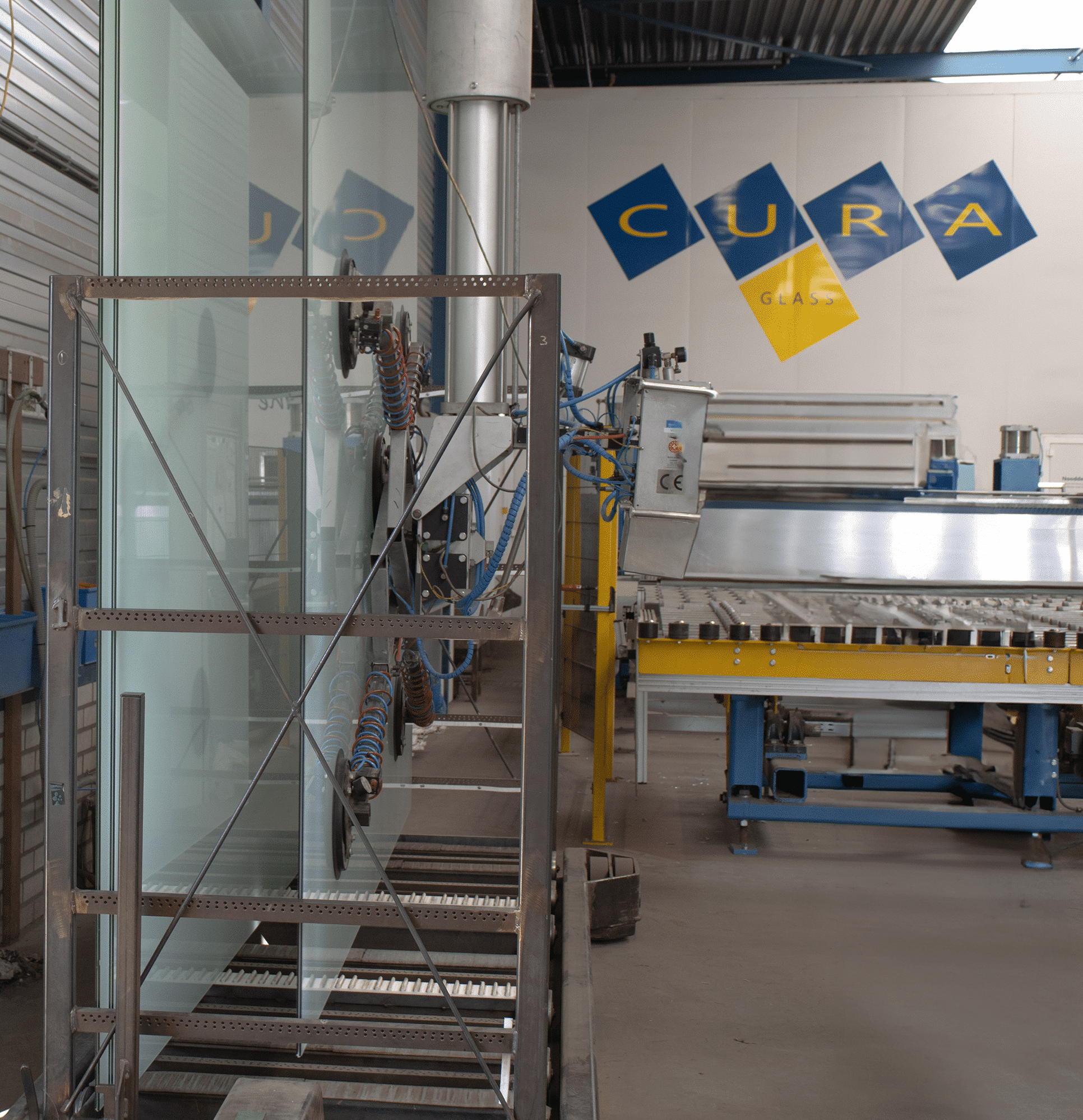

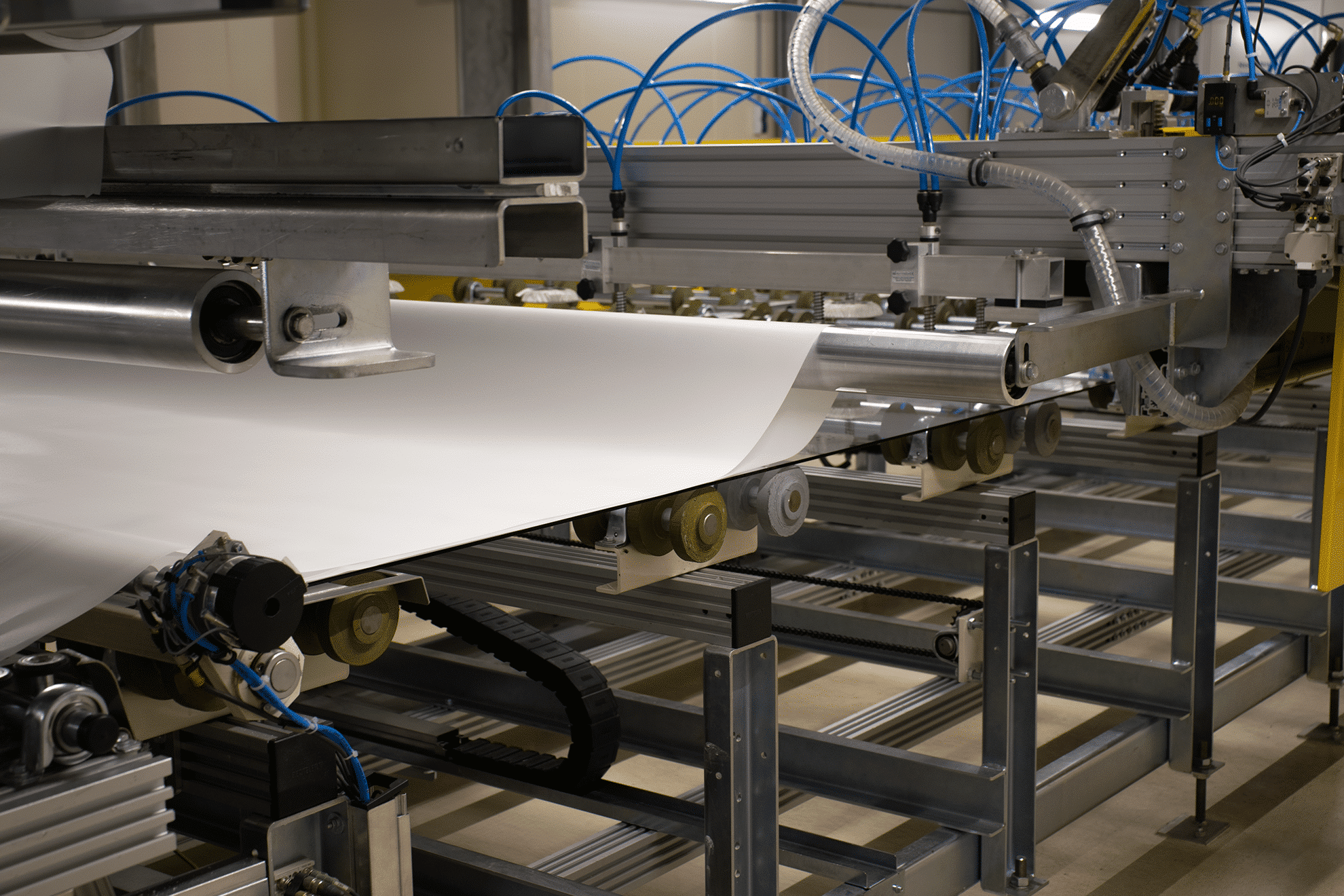

Step 3: Stacking

After the first sheet has been washed, the laminating line places the chosen interlayer(s) on the glass. Then, the second, washed sheet of glass is placed on top. This can be repeated multiple times until the desired combination is created.

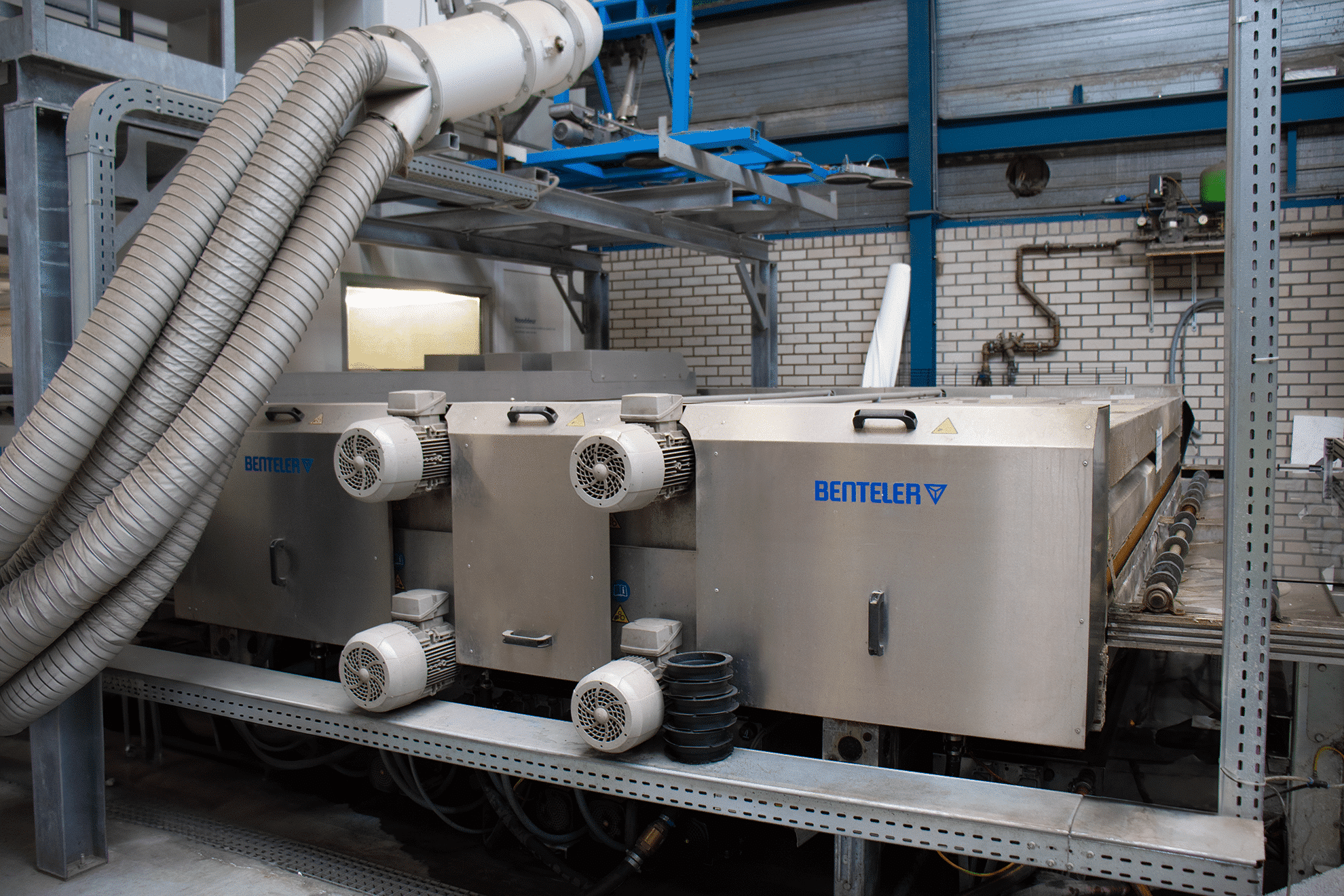

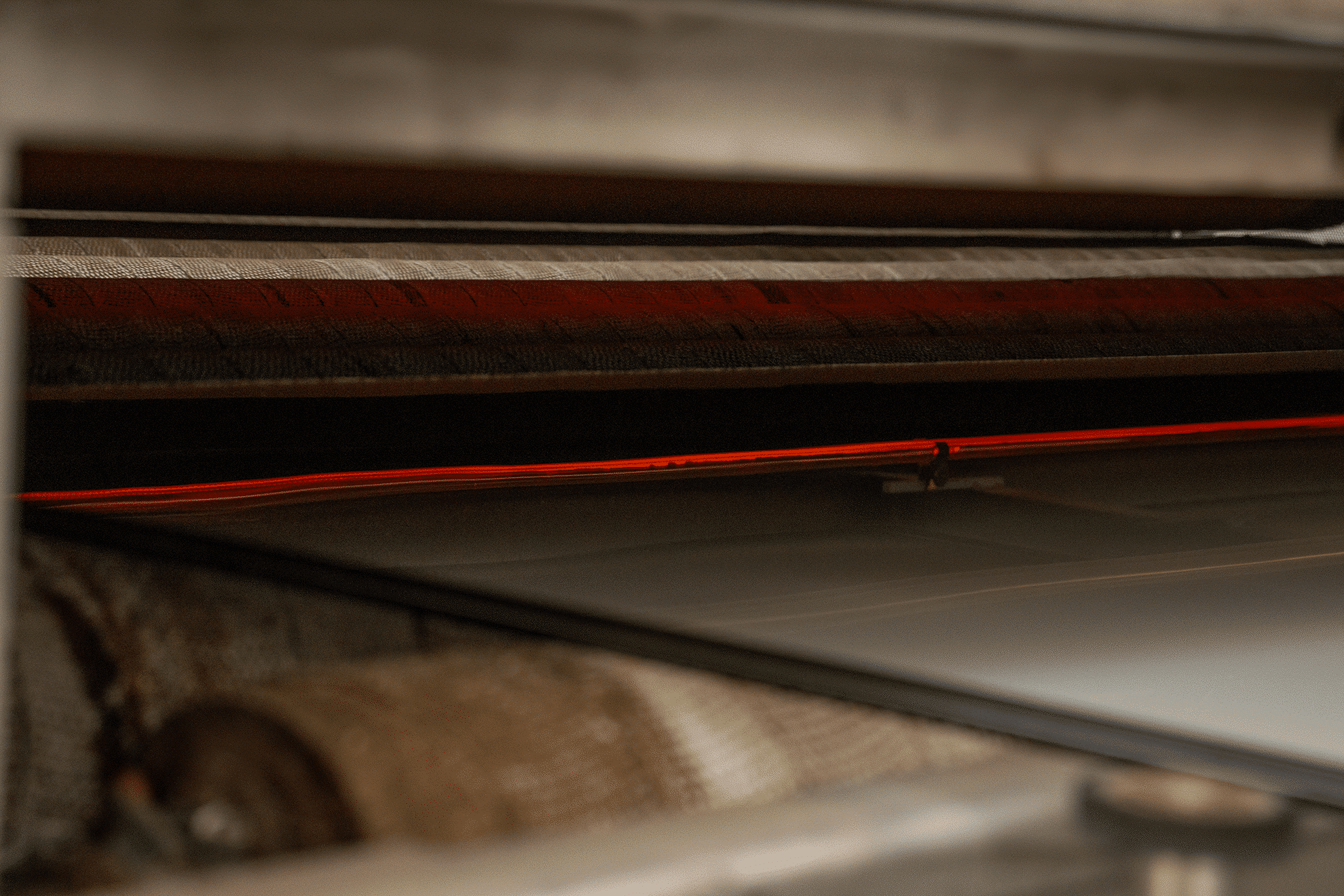

Step 5: Heating

During the fifth step, the combination is send through three ovens. The heat will cause the interlayers to attach to the glass sheets and stick them together. When the glass comes out of the oven, the core temperature is measured to make sure the pre-laminate is attached properly.

Step 7: Autoclave

In this last step, the pre-laminate will be permanently bonded under the pressure of 14 bars for three hours long. When the laminated glass comes out of the autoclave, it is ready to be shipped out.